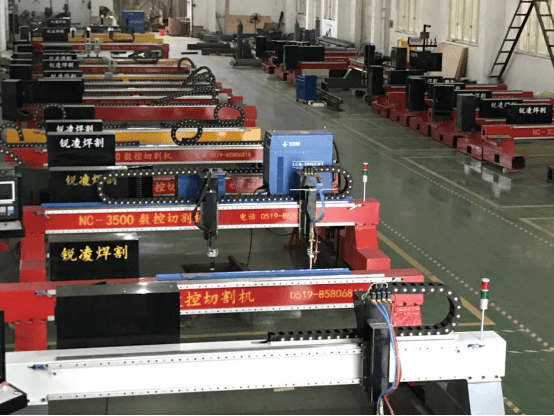

The CNC plasma cutting machine combines a simple and easy-to-use CNC system to ionize the high-speed airflow jetted from the nozzle at high temperature to form an electrical conductor.When the current passes, the conductor forms a high-temperature plasma arc. The heat of the arc locally melts (and evaporates) the metal at the incision of the workpiece, and uses the power of the high-speed plasma flow to remove the molten metal to form an incision.The slender and stable plasma arc formed by the annular airflow technology ensures that any conductive metal can be cut smoothly and economically.

Use skills of CNC plasma cutting machine

When using the CNC plasma cutting machine, its cutting quality is unstable, and the wearing parts are frequently replaced. It is found that the user is not standardized enough for the use of the CNC plasma cutting machine during operation, and at the same time, we have not paid enough attention to some details.Summarized some of the daily use skills of some CNC plasma cutting machines, hoping to bring you convenience:

1. Cutting should start from the edge

Start cutting from the edge as much as possible, instead of perforating cutting.Using the edge as the starting point will extend the life of the consumable parts. The correct method is to directly aim the nozzle at the edge of the workpiece before starting the plasma arc.

2. Reduce unnecessary "arc starting (or arc guiding)" time

When arcing, the consumption of nozzle and electrode is very fast. Before starting, the cutting torch should be placed within the walking distance of cutting metal.

3. Do not overload the nozzle

Overloading the nozzle (that is, exceeding the operating current of the nozzle) will quickly damage the nozzle. The current intensity should be 95% of the working current of the nozzle. For example: the current intensity of a 100A nozzle should be set to 95A.

4. Use a reasonable cutting distance

According to the requirements of the instruction manual, use a reasonable cutting distance, which is the distance between the cutting nozzle and the surface of the workpiece. When piercing, try to use twice the normal cutting distance or the maximum height that the plasma arc can deliver.

5. The thickness of the perforation should be within the allowable range of the machine system

The cutting machine cannot perforate the steel plate that exceeds the working thickness. The usual perforation thickness is 1/2 of the normal cutting thickness. Try to keep the cutting torch and consumable parts clean. Any dirt on the cutting torch and consumable parts will greatly affect the plasma The function of the system. When replacing consumable parts, place them on a clean flannel, check the connection ribs of the cutting torch frequently, and clean the electrode contact surface and nozzle with hydrogen peroxide cleaner.

The cutting speed of CNC plasma cutting machine is different to the cutting quality

The combination of a CNC cutting machine and a plasma power supply is called a CNC plasma cutting machine. Plasma cutting is easy to produce breaks. There are many reasons for the breaks. Generally, the best cutting speed range of the plasma CNC cutting machine can be selected according to the equipment description. Or use experiments to determine, but due to factors such as the thickness of the workpiece to be cut, different materials, high or low melting point, thermal conductivity, and surface tension after melting, the cutting speed of the plasma CNC cutting machine also changes accordingly. Its main manifestations are as follows:

1. Plasma CNC cutting machine can improve the quality of the cut when the cutting speed is increased appropriately, that is, the cut is slightly narrower, the surface of the cut is flatter, and the deformation can be reduced at the same time.

2. When the cutting speed is too fast, the plasma numerical control cutting machine makes the cutting line energy lower than the required value, and the jet in the cutting seam cannot quickly blow off the molten cutting melt immediately, resulting in a larger back drag. The surface quality of the incision decreases due to the dregs on the incision.

3. When the cutting speed of the plasma numerical control cutting machine is too low, because the cutting place is the anode of the plasma arc, in order to maintain the stability of the arc itself, the anode spot or the anode area must find a place to conduct current near the slit closest to the arc. At the same time, more heat is transferred to the radial direction of the jet, so that the incision becomes wider. The molten material on both sides of the incision gathers and solidifies at the bottom edge, forming a slag that is not easy to clean, and the upper edge of the incision is formed due to excessive heating and melting. Rounded corners.

4. When the cutting speed of the plasma CNC cutting machine is extremely low, the arc may even go out due to the wide cut. It can be seen that good cutting quality and cutting speed are inseparable.

The gas selection skills and key points of CNC plasma cutting machine

CNC plasma cutting machines usually have higher no-load voltage and working voltage. When using gas with high ionization energy such as nitrogen, hydrogen or air, the voltage required to stabilize the plasma arc will be higher. When the current is constant, the increase of the voltage means the increase of the arc enthalpy and the increase of the cutting ability. If the diameter of the jet is reduced and the flow rate of the gas is increased while the enthalpy value is increased, a faster cutting speed and better cutting quality can often be obtained.

1. Hydrogen is usually used as an auxiliary gas to mix with other gases. For example, the well-known gas H35 (the volume fraction of hydrogen is 35%, and the rest is argon) is one of the most powerful gases for plasma arc cutting, which is mainly beneficial hydrogen. Since hydrogen can significantly increase the arc voltage, the hydrogen plasma jet has a high enthalpy value. When mixed with argon, the cutting ability of the plasma jet is greatly improved.

2. Oxygen can increase the speed of cutting low carbon steel materials. When oxygen is used for cutting, the cutting mode is very similar to that of a CNC flame cutting machine. The high temperature and high energy plasma arc makes the cutting speed faster. The spiral duct machine must be used with an electrode that resists high temperature oxidation, and at the same time, the electrode is protected against arcing. Impact protection to extend the life of the electrode.

3. The air contains about 78% of nitrogen by volume, so the slagging situation formed by air cutting is very imaginary when cutting with nitrogen; the air also contains about 21% of oxygen by volume. Because of the existence of oxygen, use air The cutting speed of low carbon steel materials is also very high; at the same time, air is also the most economical working gas. However, when air cutting is used alone, there will be problems such as slagging, incision oxidation, and nitrogen increase, and the low life of electrodes and nozzles will also affect work efficiency and cutting costs. Since plasma arc cutting generally uses a power supply with constant current or steep drop characteristics, after the nozzle height increases, the current change is small, but it will increase the arc length and cause the arc voltage to increase, thereby increasing the arc power; but at the same time, it will also increase the arc power. The arc length exposed to the environment increases, and the energy lost by the arc column increases.

4. Nitrogen is a commonly used working gas. Under the condition of higher power supply voltage, nitrogen plasma arc has better stability and higher jet energy than argon, even for cutting liquid metal with high viscosity materials such as In the case of stainless steel and nickel-based alloys, the amount of dross on the lower edge of the cut is also very small. Nitrogen can be used alone, or it can be mixed with other gases to use a plasma cutting machine. For example, nitrogen or air is often used as a working gas in automated cutting. These two gases have become the standard gas for high-speed cutting of carbon steel. Sometimes nitrogen is also used as the starting gas for oxygen plasma arc cutting.

5. Argon hardly reacts with any metal at high temperatures, and the argon CNC plasma cutting machine is very stable. Moreover, the nozzles and electrodes used have a higher service life. However, the voltage of argon plasma arc is low, the enthalpy value is not high, and the cutting ability is limited. Compared with air cutting, its cutting thickness will be reduced by about 25%. In addition, in an argon atmosphere, the surface tension of molten metal is relatively large. , It is about 30% higher than in a nitrogen environment, so there will be more slagging problems. Even cutting with a mixture of argon and other gases will have a tendency to stick to slag. Therefore, it is rare to use pure argon alone for plasma cutting. The use and selection of gas during cutting of CNC plasma cutting machine is very important. The use of gas will seriously affect the accuracy of cutting, slagging and other phenomena.

Application range of air-cooled cutting torch for CNC plasma cutting machine

The air-cooled cutting torch of CNC plasma cutting machine refers to the plasma cutting torch that is cooled by air. It is mainly concentrated in the plasma power supply within 100A. Generally, CNC plasma cutting opportunities are used to match different types of cutting torches according to the thickness of the cutting plate. Here we The torch of the air-cooled CNC plasma cutting machine mentioned is mainly different from the water-cooled cutting torch. It is generally suitable for cutting and processing metal materials such as stainless steel and carbon plate below 10MM. The air-cooled cutting torch is also called air-cooled cutting. The torch, in short, is to reduce the surface temperature of the cutting torch through the natural cooling of air to achieve the purpose of long-term use. Air-cooled cutting torches have a shorter service life because of different cooling methods.

1. If the hafnium wire in the center of the electrode in the cutting torch burns 2.5-3mm; it should be replaced in time. The electrode must be completely cooled (blowing with compressed air) during replacement, otherwise the electrode base will become tight due to thermal expansion. Do not use too much force when unscrewing, otherwise the electrode base will be easily damaged. Before replacing the electrode and nozzle, check whether the inner cavity is clean, and use it after removing impurities.

2. During normal use, if you suddenly hear the sound of "scare", the arc is red, and the arc is up, you should stop using it immediately. At this time, the electrode and nozzle are damaged. If you continue to use it will damage the torch, you must replace the electrode, It can be used behind the nozzle.

3. The working current of the air-cooled cutting torch must not be greater than its rated current. If it exceeds, the cutting torch may be damaged.

4. When replacing electrodes and nozzles, the power of the host must be turned off. When the torch is not equipped with electrodes or nozzles, the torch switch cannot be pressed.

5. The compressed air used must be dry and clean. Because water vapor and oil stains are easy to conduct electricity, the spiral black lines appear on the electrode, indicating that excessive water vapor and oil stains make the electrode and nozzle cavity arc short-circuit, which can easily damage the cutting torch and fail to work normally.

6. The electrodes and nozzles in the cutting torch must not be loosened during use. The electrodes must be tightened with a special wrench, and must be checked before each use. If there is any looseness, use a special wrench to tighten at any time, but you cannot use an adjustable wrench or the like tool.

Cutting current selection of CNC plasma cutting machine

When the CNC plasma cutting machine is used correctly for high-quality and fast cutting, it is necessary to deeply understand and master the cutting process parameters. Only in this case can the plasma cutting equipment exert its maximum effect, and the workpieces cut will also reach For the best results, the following Ruiling Technology will explain to you the cutting current adjustment parameters of the plasma power supply when the plasma CNC cutting machine is cutting the workpiece, for the reference and learning of the majority of users. When the plasma CNC cutting machine cuts the workpiece, the adjustment of the cutting current of the plasma power supply is very important. It is the most important cutting process parameter, which directly determines the thickness and speed of the cutting, that is, the cutting ability. Regarding the impact, it is directly manifested in the following selection forms of the cutting current of the plasma CNC cutting machine:

1. As the cutting current of the plasma CNC cutting machine increases, the plasma arc energy increases, and the cutting ability increases, and the cutting speed increases accordingly;

2. The cutting current of the plasma numerical control cutting machine increases, the diameter of the plasma arc increases, and the thicker arc makes the incision wider;

3. Excessive cutting current of the plasma numerical control cutting machine increases the thermal load of the nozzle, and the nozzle is damaged prematurely, and the cutting quality naturally decreases, and even normal cutting cannot be performed. Therefore, the cutting current and the corresponding nozzle should be correctly selected according to the thickness of the material before cutting.