1. The functions and advantages of CNC flame plasma cutting machine:

Among the two major categories of RL CNC cutting equipment, flame cutting and plasma cutting currently have a considerable number of end users in the domestic market. For companies, choosing to use CNC cutting is not only to improve production and processing efficiency, but also to save more. The production cost, in terms of CNC flame and plasma cutting machine, can be attributed to labor cost, production cost and other aspects. In order to let more users understand the functional advantages of CNC flame and plasma cutting machine, the following will mainly focus on this Briefly explain the situation:

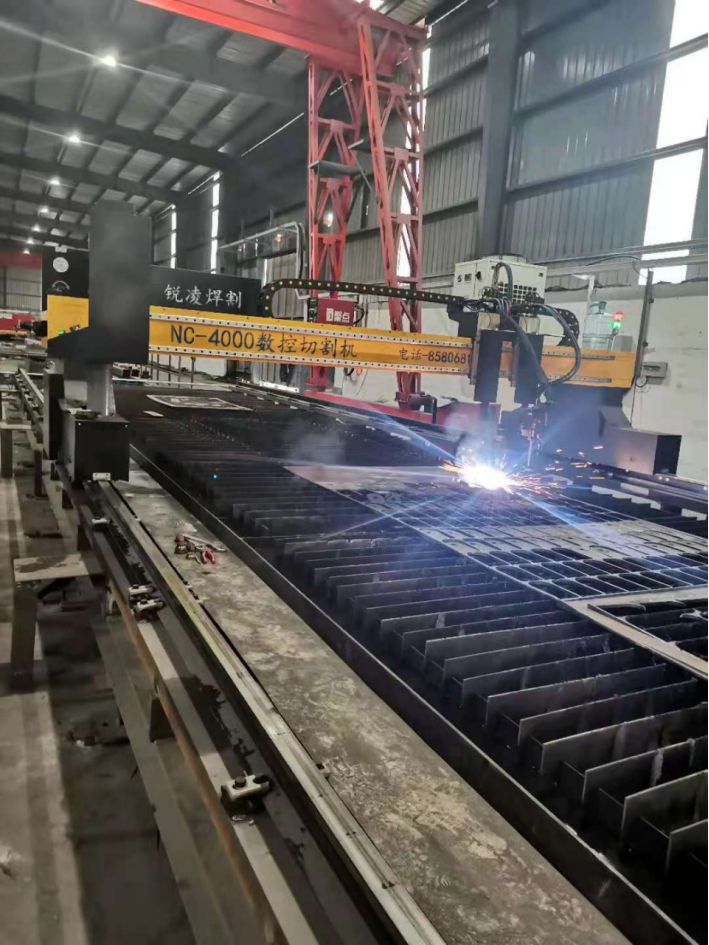

2. Introduction to Plasma Cutting

RL plasma cutting uses high-temperature high-speed gas jets at the nozzle to ionize to form electrical conductors. When the current is passed, the airflow forms a high-temperature plasma arc. The heat of the arc causes the metal at the incision of the workpiece to be partially melted (and evaporated), and the molten metal is removed by the power of the high-speed plasma airflow to form an incision. The slender and stable plasma arc formed by the annular airflow technology ensures that any conductive metal can be cut smoothly and economically. After years of exploration, the plasma technology has been developed by leaps and bounds. The recent progress is to increase the power to speed up the CNC plasma cutting machine, while improving the cutting quality. Jiangsu Ruiling Technology CNC cutting machine factory direct sales, more details can be consulted

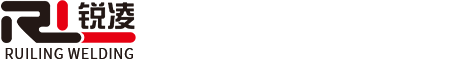

3. flame cutting introduction

RL flame cutting is the oldest thermal cutting method. The cutting metal thickness ranges from 1 mm to 1 meter or thicker, but when the thickness of most low carbon steel plates you need to cut is below 20 mm, other cutting methods should be used. . Flame cutting is to use the high temperature generated during the combustion of iron oxide to cut carbon steel. The design of the flame cutting torch provides sufficient oxygen for burning iron oxide to ensure a good cutting effect. The cost of flame cutting equipment is low and it is the only economical and effective means to cut thick metal plates, but it has its shortcomings in thin plate cutting. Compared with plasma, the heat-affected zone of flame cutting is much larger, and the thermal deformation is relatively large. In order to cut accurately and effectively, the operator needs to have superb skills to avoid the thermal deformation of the metal plate in time during the cutting process. Secondly, the speed of flame cutting is slower than that of plasma cutting. Plasma is superior in saving labor costs.